Bao’an Qu, China

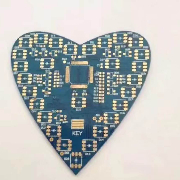

Characteristics of Heavy Copper PCB

Heavy copper PCBs offer distinct advantages in electronics, such as handling higher currents, enhancing thermal management, and providing exceptional mechanical strength. Additional characteristics include: High Mechanical Strength: Superior resistance to bending, warping, and stress, ensuring durability and reliability. Excellent Weather Resistance: Suitabl...

1.00 $