Here are some of the advantages of heavy copper PCB, let’s follow them:

1. Favorable circumstances of Heavy Copper PCB

2. Plating innovation in overwhelming copper permitted a mix of plating and carving which causes in straight sidewalls and immaterial undercut.

3. The substantial copper plating creates high-current circuits and control circuits that watches the profoundly thick and straightforward whiskers’ structure.

4. This empowers the board fabricator to build the measure of copper thickness in plated gaps and by means of sidewalls.

5. The blend of substantial copper results on a solitary board called PowerLink.

6. The substantial copper in the PCB likewise encourages in associating with the stan...

Here are some of the advantages of heavy copper PCB, let’s follow them:

1. Favorable circumstances of Heavy Copper PCB

2. Plating innovation in overwhelming copper permitted a mix of plating and carving which causes in straight sidewalls and immaterial undercut.

3. The substantial copper plating creates high-current circuits and control circuits that watches the profoundly thick and straightforward whiskers’ structure.

4. This empowers the board fabricator to build the measure of copper thickness in plated gaps and by means of sidewalls.

5. The blend of substantial copper results on a solitary board called PowerLink.

6. The substantial copper in the PCB likewise encourages in associating with the standard circuits.

7. This lessens layer tally, low impedance control conveyance, littler impressions, and potential cost investment funds.

8. For development purposes, it expands the continuance to warm strains.

9. It has expanded the current conveying limit.

10. Overwhelming copper plating brings higher current through the board and moves the warmth to the outside heat sink

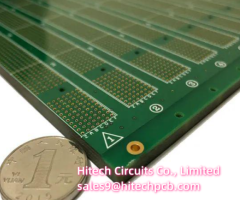

Heavy copper Printed circuit board (PCB)

Application and advantage of Heavy Copper PCB in Electronic manufacturing

Heavy Copper PCB is a special PCB, its main characteristic is that the copper thickness is greater than or equal to 2oz. Compared with traditional PCB, Heavy Copper PCB has many advantages in electronic manufacturing. For example, they can withstand higher currents, have better heat dissipation capacity, better mechanical strength and better electrical properties. These characteristics make Heavy Copper PCBs widely used in high power equipment, such as electric vehicles, industrial robots, aerospace, mobile phones, microwave, satellite communications, network base station and other fields.

Take electric vehicle electronic control system as an example, electric vehicle electronic control system is one of the core components of the vehicle, has a very important role. In this kind of high-power electronic equipment, the range of current and voltage changes is very large, and the Heavy Copper PCB has better load capacity and heat dissipation capacity, which can ensure the stability and reliability of the electronic control system. Our customers use Heavy Copper PCBs in the production of electric vehicle electronic control systems to ensure the stability and reliability of the system under high power operating conditions.

When you decide to use a Heavy Copper PCB, you need to choose the right PCB manufacturer, Hitech Circuits will be able to offer copper plates in a variety of thicknesses and specifications to suit your needs. At the same time, you should ensure that your design meets the specifications and requirements of Heavy Copper PCB, including the wiring specifications of Heavy Copper PCB, welding pad specifications, etc. Finally, the right manufacturing process is also key, such as the selection of appropriate drilling, sheet laying and other processing steps to ensure quality.

In short, Heavy Copper PCB plays an irreplaceable role in the production and application of PCB industry, with high power, high current and high cooling effect. Heavy Copper PCB manufacturing process and materials have higher requirements than standard PCB. Hitech Circuits has advanced equipment and professional engineers to supply high quality Heavy Copper PCBs to domestic and international customers.

If you want know more information pls contact sales9 at hitechpcb.com